Bender Auto Cell of Car Headrest w Kawasaki Robot

Main Features:

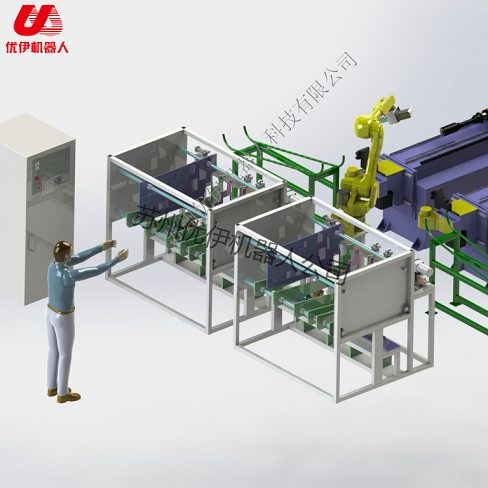

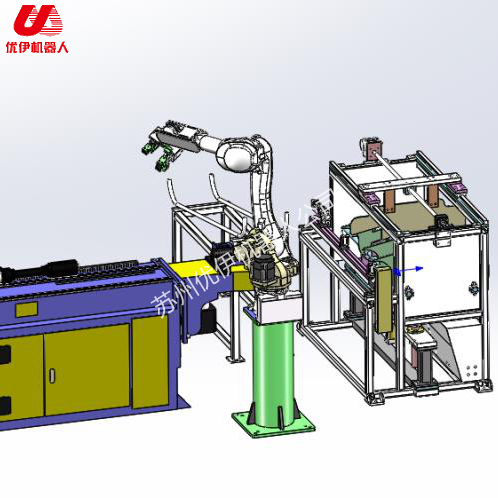

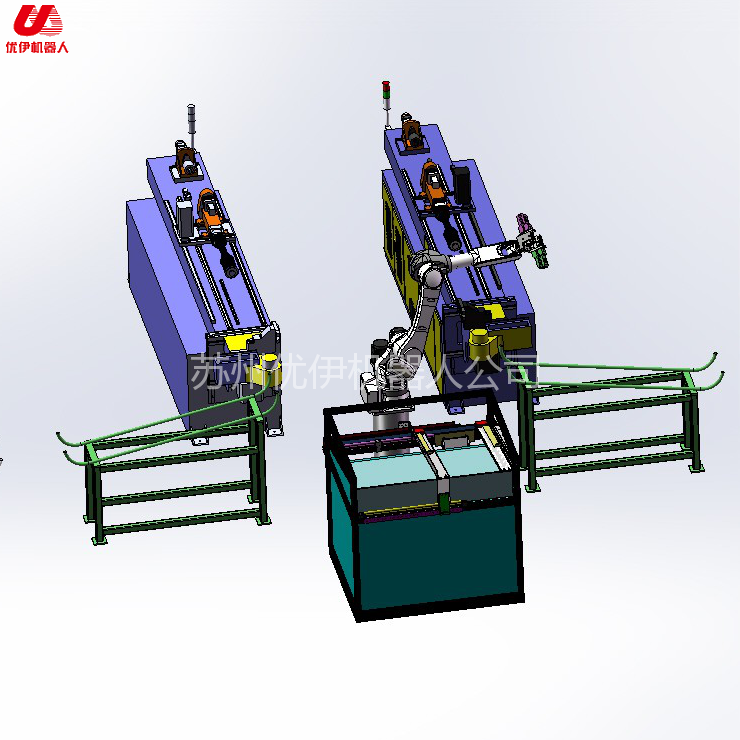

A. Robot model: Kawasaki rs-010n six axis robot (load 10kg), one;

B. Automatic feeding machine model: ue-sl-ad1200 two automatic feeding machines of Suzhou Youyi robot company;

C. Weld inspection system: servo driven automatic weld inspection positioning mechanism (option);

D. Pipe bender model: dw-cnc28-4a-2s left and right bending pipe bender;

E. Main control system: a system control cabinet of Suzhou Youyi robot company, which can adaptively control the running rhythm of all equipment in the whole system.

Product background and introduction of Kawasaki robot car headrest bar automatic line:

At present, it is not easy to find suitable workers in the production environment of automobile head bender, such as low production equipment and low production cost In the production process of automobile headrest bar, can robot or automatic equipment replace manual operation? Automatic unmanned production? The answer is yes.

Now the whole world is engaged in automation and informatization. It is the trend of the times to use robots to replace manual work. After continuous exploration and research and development in recent years, Suzhou Youyi robot company has realized the use of one industrial robot to tow two pipe benders, thus realizing the robot unmanned automatic production.

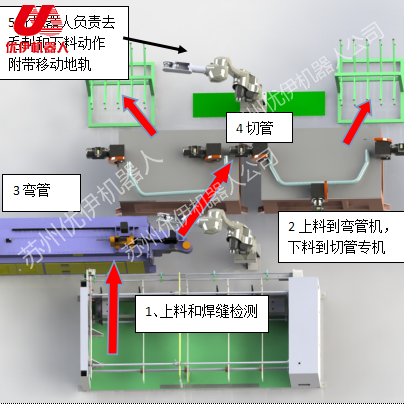

The production line is composed of one Kawasaki robot rs-010n, two ue-dw28cnc-4a-2s left and right bending pipe benders, two automatic feeding machines and master control system. The production capacity and speed are equivalent to manual operation, because the processing time of pipe bender can not be accelerated, but there is no special toilet, drinking water and rest between workers in the robot unmanned automatic line The overall efficiency is higher than that of manual operation.

The unmanned automatic production line also has an advantage that it can start up day and night without interruption. If an enterprise starts several similar production lines at the same time, it only needs one person to manage the automatic production line, batch feeding and quality inspection of the automatic production line. Therefore, under certain conditions, the enterprise can consider 5-8 similar production lines according to its own situation The ratio is relatively high, and the recovery period of automation investment funds will be very short.

If you have any demand for unmanned automatic production, please call 189-1569-8967, manager

Bender Auto Work Cell of Car Headrest and Kawasaki Robot

UE Robots

Suzhou Youyi Robot Technology Co., Ltd

Mobile:189-1569-8967

E-mail:kevin818@126.com

Adress:No.16 Zhenfeng Road, Nanfeng Town, Zhangjiagang City, Jiangsu Province

Related Products

- HJM Pipe Bender w Kawasaki Robot Loading and Unloading

- HJM Pipe Bender w Kawasaki Robot Loading and Unloading

- Automobile Headrest Robot Auto Cell (economical)

- Automobile Headrest Robot Auto Cell (economical)

- Pipe Bender w Kawasaki Robot Auto Cell

- Pipe Bender w Kawasaki Robot Auto Cell

Mobile:189-1569-8967

E-mail:kevin818@126.com

Address:No.16 Zhenfeng Road, Nanfeng Town, Zhangjiagang City, Jiangsu Province